Automatic with CNC, single support WST 83.00

Purpose: to carry out mobile turning without rolling car and locomotive wheelsets out both in depot and in the field conditions.

Price on request, USD

depending on configuration

Technical specifications

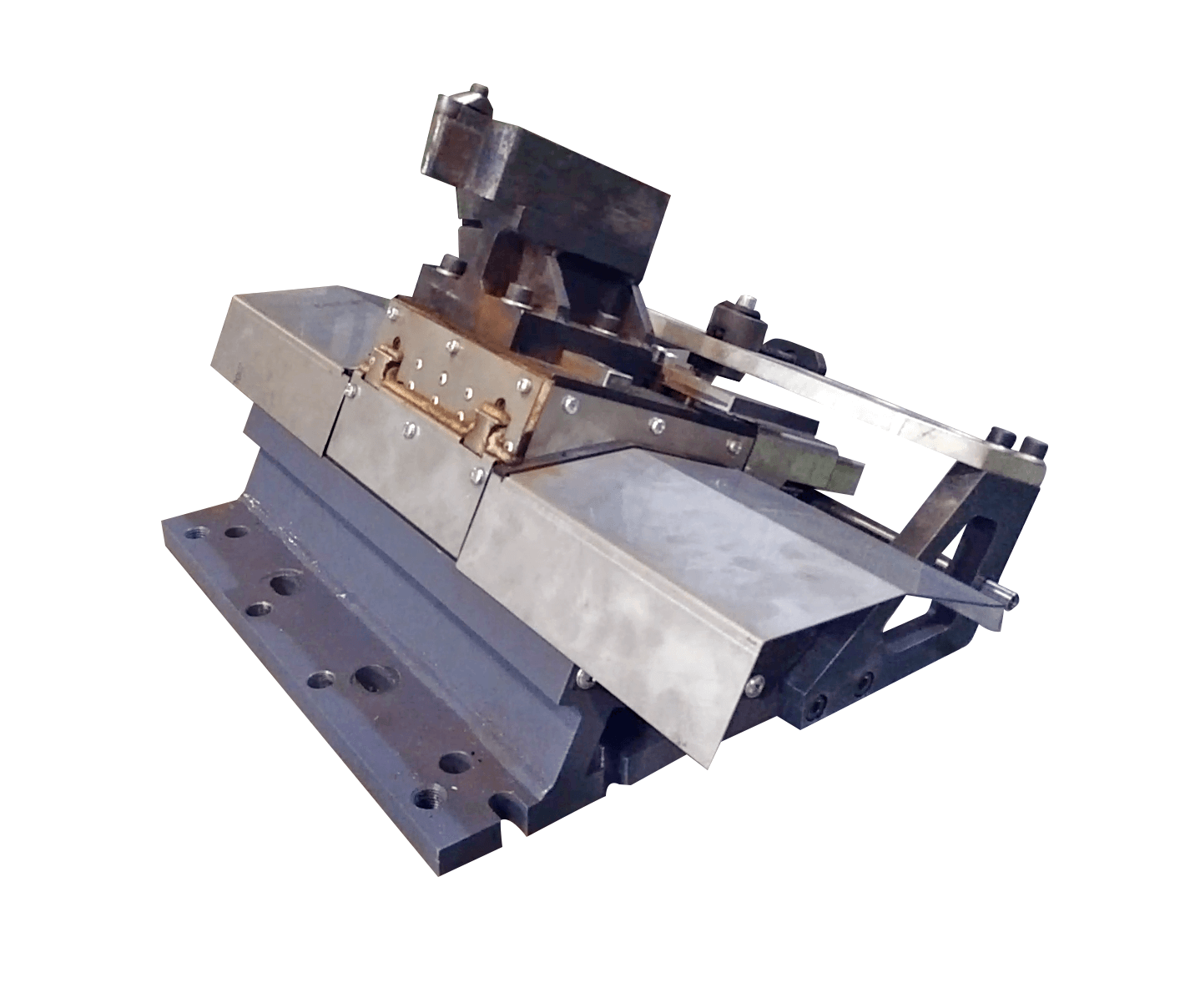

- The lathe weighs 84 kg and has a non-detachable structure, ensuring substantial metal removal of 2 to 6 mm (in diameter) per pass. This deep removal capacity allows the elimination of defects on the wheel surface, such as dents and slippage, on the first pass, resulting in savings on cutting tools and a reduction in total machining time.

- The average time for machining a wheelset is 2,5 to 4 hours.

- The lathe is easily adaptable to the technical requirements legally determined in the country.

About the lathe

- Fully automatic control from the remote control. The operator's task is to select the required profile, start the program and then… remove the chips at the end of the operation;

- The electrical supply is single-phase, with 220V;

- Reliable protection of the lathe mechanics against chips by means of stainless steel covers;

- Both axes are implemented in linear roller guides;

- The longitudinal movement (Z axis) is carried out according to the mandatory rules for turning, more specifically, along the axis towards the center of the wheel. This increases the durability of the cutter and guarantees a more accurate profile after machining;

- For turning wheelsets without engines of freight and passenger locomotives, or diesel locomotives, the lathes are additionally equipped with a drive system for rotation of the wheelsets;

- The lathe's CNC system is adapted to operate in conjunction with the CALIPRI measuring tool, allowing the calculation of the ideal profile for machining of each specific wheel.

The lathe is versatile and can be installed both on rails with exposed heads and on rails embedded in concrete, without the need to previously prepare the location for installing the lathe.

Installation on rail embedded in concrete. The lathe is installed on the rail head.

Installation on exposed rail.

Automatic with CNC, double support WST 83.00-2

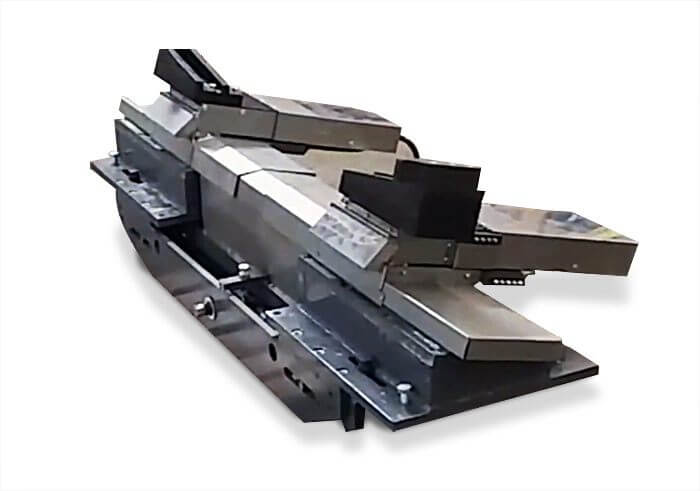

The objective is to carry out mobile turning of the wheelsets of cars and locomotives both in alternating and simultaneous mode of both wheels, but only under depot conditions. At the same time, the lathe can be moved between inspection pits with the help of a crane. Movement along the pit is carried out using centering guides placed at the bottom of the pit.

Price on request, USD

depending on configuration

About the lathe

- Fully automatic control from the remote control. The operator's task is to select the required profile, start the program and then… remove the chips at the end of the operation;

- Reliable protection of the lathe mechanics against chips by stainless steel covers;

- All axes are implemented in linear roller guides;

- The longitudinal movement (Z axis) is carried out according to the mandatory rules for turning, more specifically, along the axis towards the center of the wheel. This increases the durability of the cutter and guarantees a more accurate profile after machining;

- The control cabinet is built into the lathe carriage structure, which increases mobility and reduces the number of cable routes, with only one 220V power cable.

Turning of an independent motor-wheel unit

Technical specifications

- The electrical supply is single-phase, with 220V;

- The lathe weighs 650 kg and has a non-detachable structure, ensuring substantial metal removal of 2 to 6 mm (in diameter) per pass. This deep removal capacity allows the elimination of defects on the wheel surface, such as dents and slippage, on the first pass, resulting in savings on cutting tools and a reduction in total machining time.

- The average time to machine a wheelset is 1 to 4 hours.

- The lathe's CNC system is adapted to operate in conjunction with the CALIPRI measuring tool, allowing the calculation of the ideal profile for machining each specific wheel.

Additional equipment

Moves mobile lathes and rotary drive in depots and in the field.

- a special platform that allows to easily and quickly install equipment on the rail;

- hydraulic lifting device;

- high passability.

Measures the parameters of the wheel, brake discs, switch, rails without contact with the object.

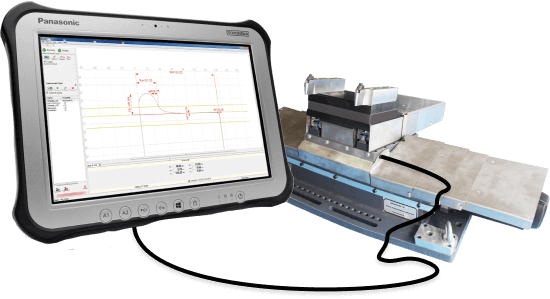

- supports exporting measurement results to a PC, tablet or CNC machine;

- integrates with a CNC lathe WST 83.00.

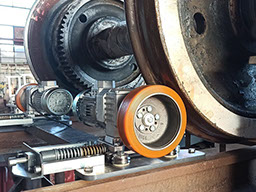

Rotates wheelsets with traction motors on DC locomotives.

- supports MIG-MAG mode;

- currency strength - 500 A;

- supply voltage - 380 V.

Rotates non-motorized wheelsets.

- high-precision control from the controller;

- based on servomotors;

- adaptive change in the speed of rotation of the drive rollers depending on the position of the lathe cutter;

- a constant torque on the wheelset is maintained;

- metal drive rollers;

- patent for invention No. 2685817

Rotates wheelsets with asynchronous traction motors on rolling stock.

- works in scalar or vector mode;

- remote control panel;

- power - 160 kW;

- supply voltage — 380 V.

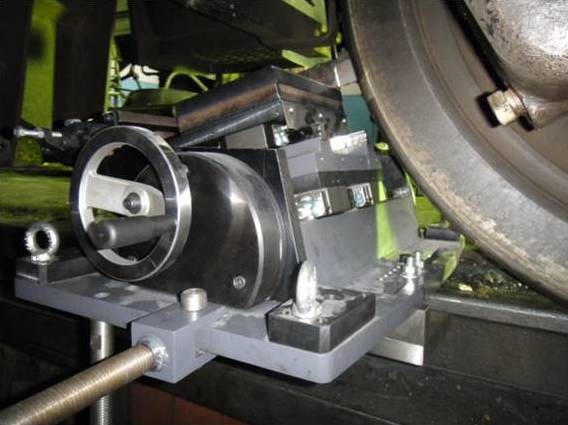

Drive for rotating a non-motorized wheelset WSRD 83.00

Rotates non-motorized wheelsets

- high-precision control from the controller;

- based on servomotors;

- adaptive change in the speed of rotation of the drive rollers depending on the position of the cutter of the machine;

- a constant torque is maintained on the wheelset;

- metal drive rollers;

- patent for an invention №2685817

Available modifications

The built-in copier minimizes the human factor when turning and restoring the profile. The copier is made according to standard profile types from the CT-329 instruction, or in special execution.

The feeding mechanism does not require much effort.

It can be upgraded step by step to the MKS 83.00 machine with CNC and adaptive tuning, as well as equipped with a drive for rotating non-motor wheelsets. WSRD 83.00.

The CNC contains programs with built-in profiles that comply with the GOST standard 11018-2011 and instruction ЦТ-329.

The software interface of the CNC controller in russian language.

Data transfer interface to ERP and MES systems (Industry 4.0 concept).

Compatible with Calipri profilometer. When working in pairs, it reduces the turning time.